Industrial Engineers and Manufacturing Improvement Engineers

We Help People In Manufacturing Improve Process and Productivity – Reduce Business Costs – Increase Profits, Cash Flow.

.

We Are LEAN Industrial Engineers – Manufacturing Improvement Engineers.

We.help.people.in.business.improve their business and reduce costs.

- We design and organise factories to improve processes.

- We find, drive and implement process improvements.

- We implement improvements to increase profits

We Can Help You With:-

- Factory Organisation

- Warehouse Organisation

- Lean Process Improvement

- Time and Motion Study Analysis

- Write Work and Quality Procedures

.

We Can Help You:-

- Implement LEAN

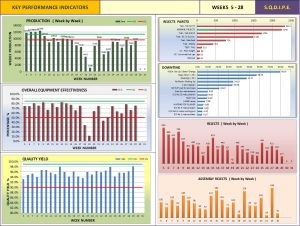

- Improve KPIs, OEE

- Reduce Scrap Levels

- Improve Product Quality

- Improve Process & Efficiency

- Improve Cash Flow and Profits

.

Services We Offer:-

- Visual Management / Key Performance Indicators

- Process Mapping / Value Stream Mapping

- Work Study and Method Study

- Cycle Time Measurement

- Factory Floor Layout Design

- Machine Breakdown Analysis & TPM

- Write Standardised Work Process Procedures

- Workstation Design: Single-piece-flow – Line Balancing

- Workplace Organisation: Lean Process Design – Cell Design

- Warehouse Organisation: Inventory, Supermarket, Kitting, Kanban

- Energy Management To reduce Energy Waste – Help in the Race Towards ZERO

- Methodologies: Lean – Six Sigma – 7S – KPI – SPC – OEE – SMED – TPM – DFA – DFM – MTM – WCM

If You Have Any Questions, We Are Happy To Help:

Benefits Delivered: Generated £50k to £2.0M Per Project – Return.On.Investment. 13/1

Atherton Management Services Ltd: We help people in business improve their business.

For More Information – Please call us… UK – 07300 788 486 or Contact Us By E-Mail