COST SAVING INITIATIVES IN MANUFACTURING COMPANIES

.

Cost Saving Ideas and Initiatives In The Workplace

REDUCING BUSINESS COSTS:- Starts With The Reduction Of Non-Value Waste…

LEAN Manufacturing Principles: Are the foundation for improving processes and reducing manufacturing costs – They are the building blocks to improved process, productivity, profit, future growth and cash in the bank…

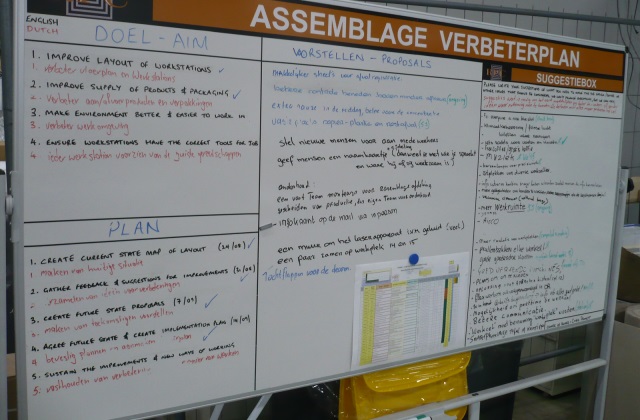

Simple Cost Savings initiatives made for a number of our clients are illustrated below…

.

COST SAVING IN INITIATIVES:

- 1.Reduce Non-Value & Scrap

- 2.Lean Process Improvement

- 3.Factory Layout Organisation

- 4.Stock & Inventory Organisation

- 5.Product Quality Improvement

- 6.Written Std Work Procedures

CLIENT COST SAVING INITIATIVES:

- Inventory Cost Reduction £28,000

- Scrapping Material Reduction £64,000

- Customer Complaint Reduction £88,000

- Production Cost Savings circa £425,000

- Late Delivery Cost Savings circa €500,000

- Manufacturing Improvement circa £927,000

- Manufacturing Improvement circa €1,000,000

WE HELP people implement simple cost saving initiatives for manufacturing companies businesses & in the workplace. We Are LEAN Manufacturing Project Management Specialists UK

Opportunity and a fresh pair of eyes is all that is needed…

.

If You Have Any Questions, We Are Happy To Help:

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Atherton Management Services Ltd: We help people in business improve their business

Please Contact Us, tell us your issues – tell us how you would like to improve your business

For More Information – Please call us… UK – 07300 788 486 or Contact Us By E-Mail