Manufacturing Process Improvement and Engineering

.

CASE STUDY

BUSINESS TRANSFORMATION

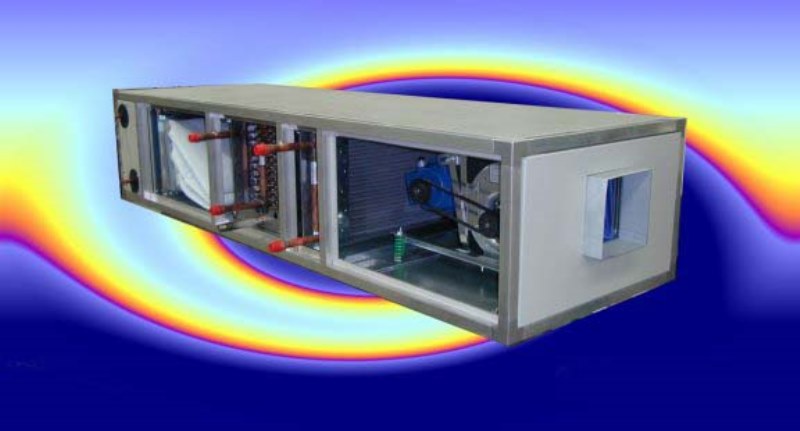

The company manufacture high quality HVAC equipment and supply it to financial organisations, hospitals, retail and industrial organisations. They felt that ‘Lean application’ could improve their product further and would give them the competitive edge in order to increase business and profits.

.

PROCESS OF TRANSFORMATION

- Operator activity analysis

- Floor design and re-layout

- Standardise product range

- Measure operational cycle times

- Write Standard Assembly Manual

- Implement improved methods of manufacture

- Reduce inventory and manufacturing build costs

.

Area of Improvement Savings

- Labour Time Savings………..£45,000

- Inventory Cost Reduction……£28,000

- Material Scrap Reduction……£64,000

- Customer Complaint Reduction £88,000

- Energy Management Reduction £4,200

This Project Case Study Illustrates what can be achieved with a fresh pair of eyes circa £229k

Opportunity and a fresh pair of eyes is all that is needed…

.

If You Have Any Questions, We Are Happy To Help:

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Atherton Management Services Ltd: We help people in business improve their business

Please Contact Us, tell us your issues – tell us how you would like to improve your business

For More Information – Please call us… UK – 07300 788 486 or Contact Us By E-Mail