HOW TO Improve Process Efficiency: Manufacturing Workplace UK

WE HELP Manufacturing Businesses: Simple Cost Saving. In the Clothing Industry Workplace – WE ARE Process Improvement Engineers & Consultant Services

.

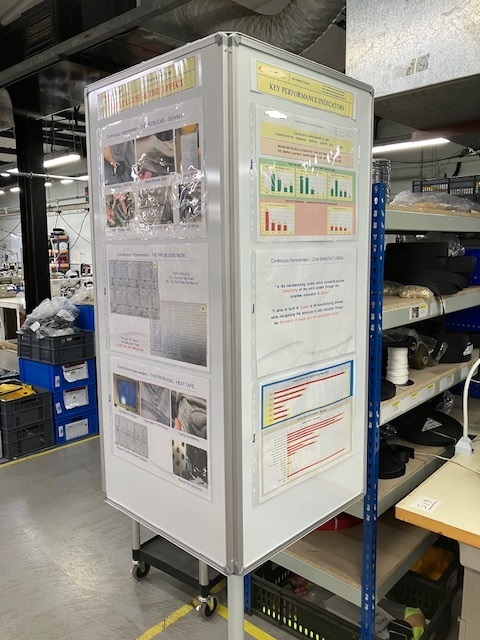

Clothing: Factory Organisation Case Study

.

CASE STUDY IMPLEMENTED

- OBJECTIVES:– To improve processes, line efficiency and reduce manufacturing costs

- RESULTS:- De-cluttered stores – Re-engineered floor layout – Raised all working standards

- BENEFITS:- Improved efficiency – Sales and business growth potential overall yield circa +30%

FINANCIAL BENEFITS:

Process improvement could produce circa 30% more production. And £2M in sales revenue.

.

.

PROJECT WORK DONE:

- 1.Listen to the client

- 2.Draw present state factory layout

- 3.Re-engineer to a LEAN floor layout

- 4.The introduction of Section Kitting Areas

- 5.The introduction of Daily Production Targets.

- 6.Stores organisation to include 7S – Kanban – Min/Max levels

- 7.The sourcing of materials and “on time delivery from suppliers”

- 8.Root Cause Analysis of all process issues including test and quality

- 9.Value Stream Mapping of Process and Reduction of Non-Value Waste

- 10.Continuous Improvement Planning for Future Projects

- 11.The Introduction of Quality Awareness Procedures

- 12.Operator Training and Quality Awareness

.

.

A “Fresh Pair Of Eyes” is the KEY to Implement Simple Process Improvements & Reduced Costs

.

PROJECT RESULTS:

- Process Improvement

- Production Improvement

- Product Quality Improvement

- Product Throughput Improvement

- Stores and Inventory Organisation

- Sales and Business Growth Potential

.

.

Over the years we’ve generated for clients £50k to £2.0M per project. Ave Return On Investment 13/1

Tell Me Your Ideas – I Can Help You Achieve Them

.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail…