ENERGY MANAGEMENT – Manufacturing Industrial Engineer

We Help Manufacturing Companies & Industry: LEAN Energy Management & Cost Savings – Implementing Process Improvements

.

YOU CAN’T SEE ENERGY WASTE – OR CAN YOU ?

.

ENERGY WASTE CAUSE:

- Making rejects

- Re-making product

- Operators not well trained

- Lighting ON when NOT needed

- Over Processing and Over Production

- Lights, Heating, Machines left ON at night

.

PRACTICAL STEPS TO KEEP YOUR ENERGY BILLS LOWER

.

ENERGY MANAGEMENT SOLUTIONS:

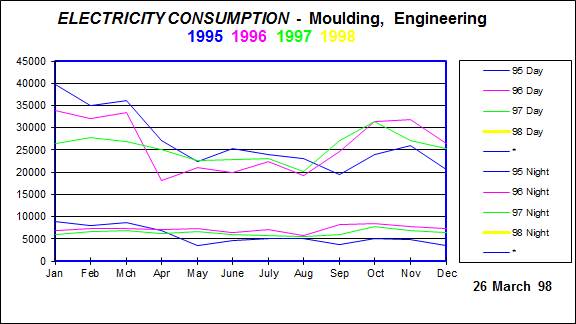

- Monitor Energy Use: Electric, Gas, Water, Air Leaks

- Listen for AIR LEAKS, WATER DRIPS and repair

- Turn OFF machines and lighting when not in use

- Training People: Energy Waste Awareness

- Implement: TPM / SMED / LEAN / KPIs

- Adopt the “Right First Time” policy

- Look Beyond The Obvious…

SO:- What Is The Cost To YOUR Business – By Doing Nothing…

The Way To Reduce Energy Bills – Is To Eliminate Non-Value Waste

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail