ENERGY MANAGEMENT: Manufacturing Solutions Services UK

WE HELP Manufacturing Companies and Industry: LEAN Energy Management and Cost Savings – WE ARE Continuous Improvement Engineers Consultants UK

.

YOU CAN’T SEE ENERGY WASTE – OR CAN YOU ?

.

ENERGY WASTE IN MANUFACTURING:

- Making rejects

- Re-making product

- Operators not well trained

- Lighting ON when NOT needed

- Over Processing and Over Production

- Lights, Heating, Machines left ON at night

- Machines Breaking Down – Poor Product Quality

.

PRACTICAL STEPS TO KEEP YOUR ENERGY BILLS LOWER

.

THINGS YOU CAN DO IN MANUFACTURING:

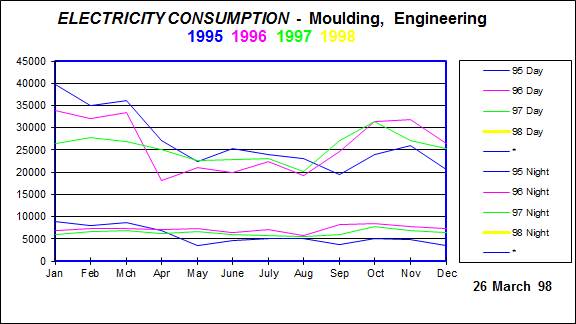

- Monitor Energy Use: Electric, Gas, Water, Air Leaks

- Listen for AIR LEAKS, WATER DRIPS and repair

- Turn OFF machines and lighting when not in use

- Training People: Energy Waste Awareness

- Implement: TPM / SMED / LEAN / KPIs

- Adopt the “Right First Time” policy

- Look Beyond The Obvious…

.

How Can I Help You, With Your Ideas

.

We Offer You Hands-On-Help to Improve Processes and Reduce Costs

.

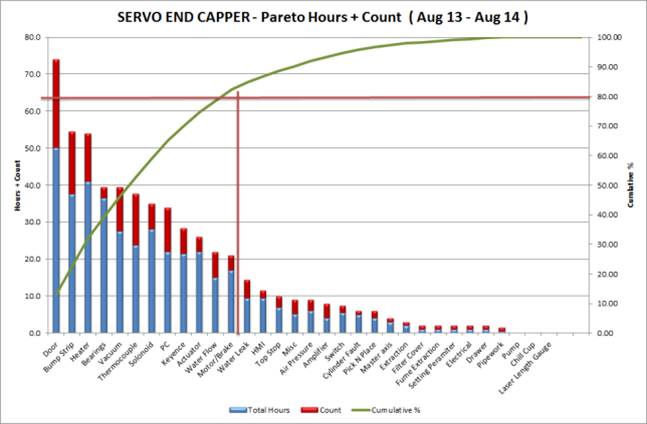

OEE Improvement Engineering Will Reduce Energy Bills

OEE Improvements In Manufacturing: Machine Stoppages, Breakdowns, cost industry thousands of Pounds / Yr. Improving OEE: We can help you reduce your energy bills.

Energy Management In The Manufacturing Industry

Total Productive Maintenance Engineering: Is the strategy to service plant & machines, so they don’t breakdown… Implementing TPM: Will reduce your energy costs, improve production, productivity and profits

.

Simple TPM Improvement Implementation:

- Root Cause – Pareto

- Develop Machine Listing

- Develop Machine History

- Develop Stock Parts Listing

- Develop Servicing Check Sheet

- Develop Housekeeping and H&S Routine

Financial Benefits:

- Cheaper Bills – Better Cash Flow – Higher Profits

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail