COST SAVING IDEAS: In Business Manufacturing Workplace UK

WE HELP Manufacturing Company Business Workplace Warehouse Simple Cost Saving Ideas – WE ARE Time & Motion Study Industrial Engineers & Consultants

.

We Help People In Manufacturing Improve Processes & Reduce Costs

.

We are a small Independent Ltd Company that provides Simple Cost Effective Process Improvements..

We Are Industrial Engineers Consultant Specialists in improving manufacturing processes, productivity, efficiency. With a continuous improvement strategy to reduce costs. And improve your business and growth potential.

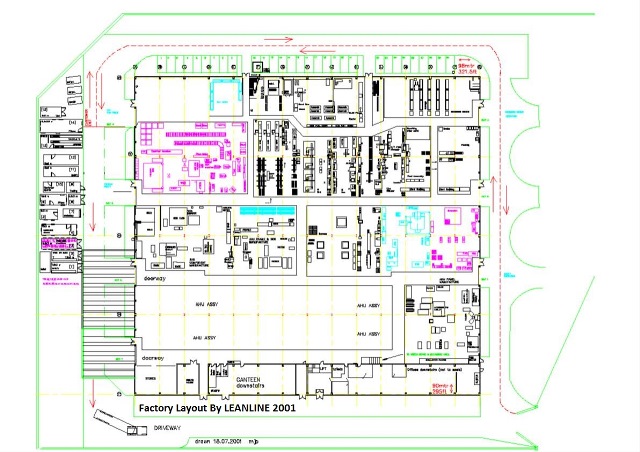

- We design and organise factories to improve processes.

- We find, drive and implement process improvements.

- We implement improvements to increase profits.

- We Can Help You Reduce Costs

How Can We Help You, With Your Ideas

All photographs are from projects we have successfully implemented

We Offer You Hands-On-Help to Improve Processes and Reduce Costs

.

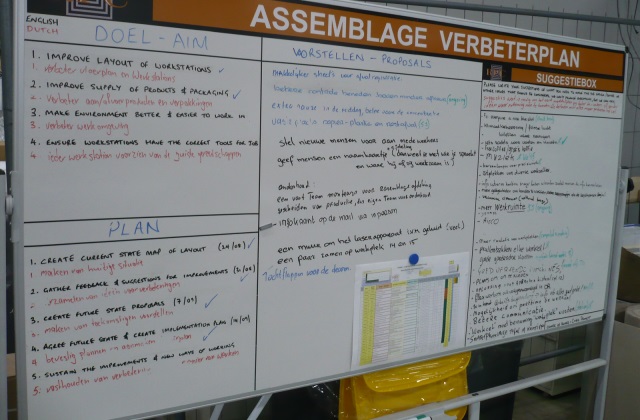

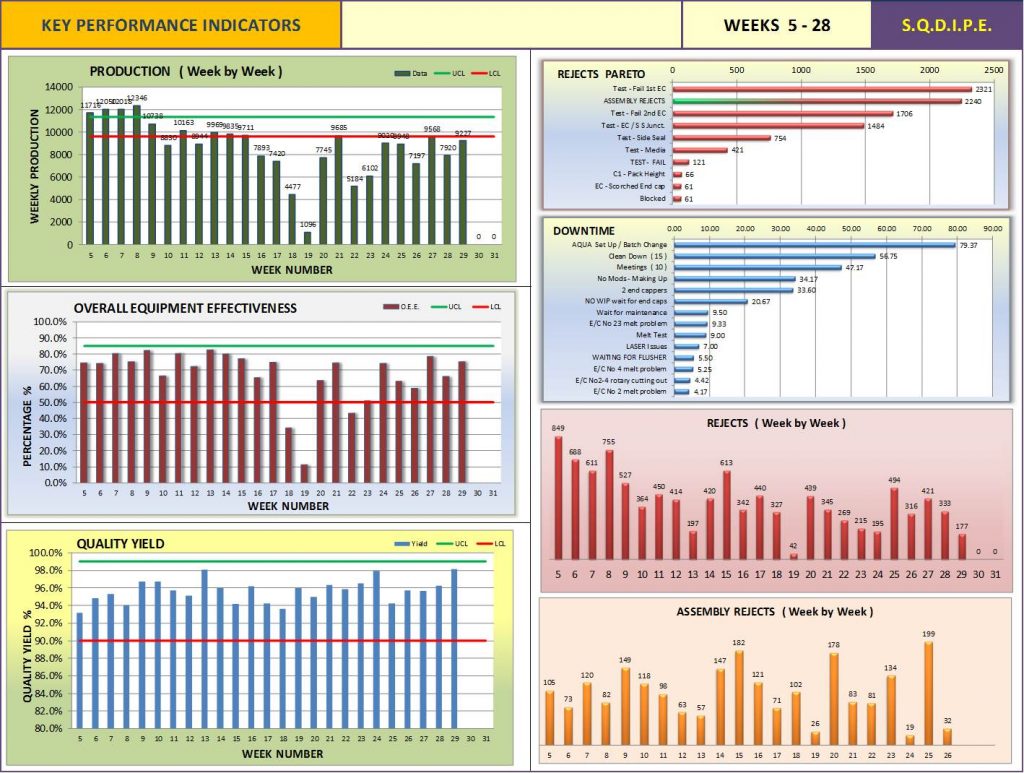

- Visual Management / Key Performance Indicators

- Process Mapping / Value Stream Mapping

- Work Study and Method Study

- Cycle Time Measurement

- Factory Floor Layout Design

- Machine Breakdown Analysis & TPM

- Write Standardised Work Process Procedures

- Workstation Design: Single-piece-flow – Line Balancing

- Workplace Organisation: Lean Process Design – Cell Design

- Warehouse Organisation: Inventory, Supermarket, Kitting, Kanban

- Energy Management To reduce Energy Waste – Help in the Race Towards ZERO

- Methodologies: Lean – Six Sigma – 7S – KPI – SPC – OEE – SMED – TPM – DFA – DFM – MTM – WCM

Over the years we’ve generated for clients £50k to £2.0M per project. Ave Return On Investment 13/1

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail…