HOW TO REDUCE COSTS: Manufacturing Business Workplace UK

WE HELP Manufacturing Businesses: How to Cut & Reduce Costs in the Engineering Workplace – WE ARE Process Improvement Engineers & Consultant Services

.

HVAC Manufacturing Transformation Case Study

.

CASE STUDY IMPLEMENTED

- OBJECTIVES:- To improve processes, line efficiency and reduce manufacturing costs

- RESULTS:- Implemented Std Times and Work Procedures – Improved product end-end turnaround

- BENEFITS:- Improvements would give the client the competitive edge to increase business and profits

FINANCIAL BENEFITS:

Project Potential Savings Per Annum circa £229k

.

.

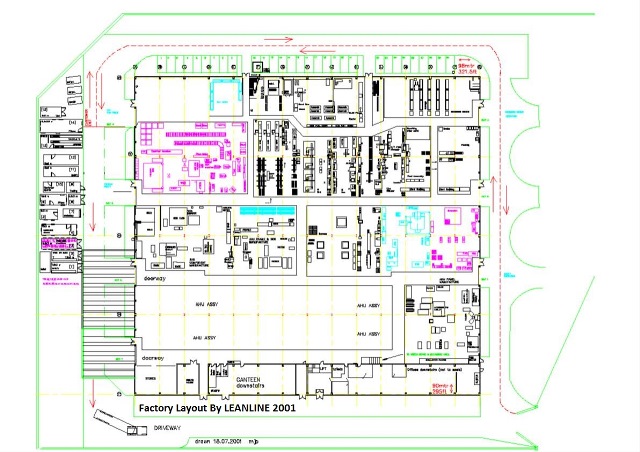

PROJECT WORK DONE:

- Operator activity sampling

- Floor re-layout 90,000 sq.ft.

- Standardise product range

- Time and Motion improvements

- Write a Standard Op Assembly Manual

- Implement new methods – reduce build costs

.

.

A “Fresh Pair Of Eyes” is the KEY to Implement Simple Process Improvements & Reduced Costs

.

.

PROJECT RESULTS:

- £45,000 – Labour Time Savings

- £28,000 – Inventory Cost Reduction

- £64,000 – Material Scrap Reduction

- £88,000 – Customer Complaint Reduction

- £4,200 — Energy Management Reduction

.

Over the years we’ve generated for clients £50k to £2.0M per project. Average Return On Investment 13/1

Tell Me Your Ideas – I Can Help You Achieve Them

.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail…