CONTINUOUS IMPROVEMENT: Engineer & Consultant Services UK

We Help People in Manufacturing Improve Processes, Productivity and Profits – Reduce Costs – We Are Continuous Improvement Engineers & Consultants UK

.

Business Support For The UK Manufacturing Industry:

.

We Are LEAN ENGINEERS Specialists in improving manufacturing processes, productivity, efficiency. With a continuous improvement strategy to reduce costs. Business Support for 30+ years.

- We design and organise factories to improve processes.

- We find, drive and implement process improvements.

- We implement improvements to increase profits.

- We Can Help You Reduce Costs

- Tell Me Your Ideas – I Can Help You Achieve Them

How Can I Help You Improve Your Business ?

.

Continuous Improvement Methodologies and Project Management Services:

.

Change Management…6 SIGMA

- Define- The Project Improvement Plan

- Measure- The current process. Collect data

- Analyse- The data to verify root causes and ideas

- Improve- The process from ideas produced – Implement

- Control- The process. Create Standard Operating Procedures

- YOU – Benefit From Improved Processes and Reduced Costs

.

Non-Value Reduction…TIM WOOD

- 1.Transportation- Excessive movement of “anything”.

- 2.Inventory- Over Stocked “Stuff” on a shelf collecting dust.

- 3.Motion- Movement of the body. Reaching, Bending, Walking.

- 4.Waiting- People Idle not producing. Waiting for parts or people.

- 5.Over Production- Making too many or too much, parts not required.

- 6.Over Processing- Too many operations in the process. End-to-End.

- 7.Defects- Re-Works, Repairs, drawing mistakes, machining error.

- 8.Resources- People. The 8th Waste… People Idle.

.

Production Floor Organisation…5S

- 1.SORT. What is Needed, Remove what is not…

- 2.SET. Organise What is Needed.

- 3.SHINE. Tidy Area and Keep Clean.

- 4.STANDARDISE. & Reduce Variation.

- 5.SUSTAIN. Maintain with Process Controls.

- 6.SAFETY. A Place for Everything – Everything in it’s Place

- 7.SELL. Everything today has value to someone.

.

Inventory Organisation…KANBAN

- Optimise Stock Levels

- Management of Stock Levels

- Organise & Optimise Pick-Zones

- Controls that Improve Cash Flow

- De-clutter work areas and stores

.

Single Minute Exchange of Die.SMED

- Reduction of Non-Value

- Reduction of Changeovers

- Reduction of Machine Set Up Time

- Increased Production and Productivity

- De-clutter work areas and tool store

.

Total Planned Maintenance…T.P.M

- To Improve Machine Up-time

- To Keep Machines Hitting Targets

- To Increase Production and Productivity

- To Increase Sales from Global Business Growth

- To Reduce Manufacturing Unit Costs

.

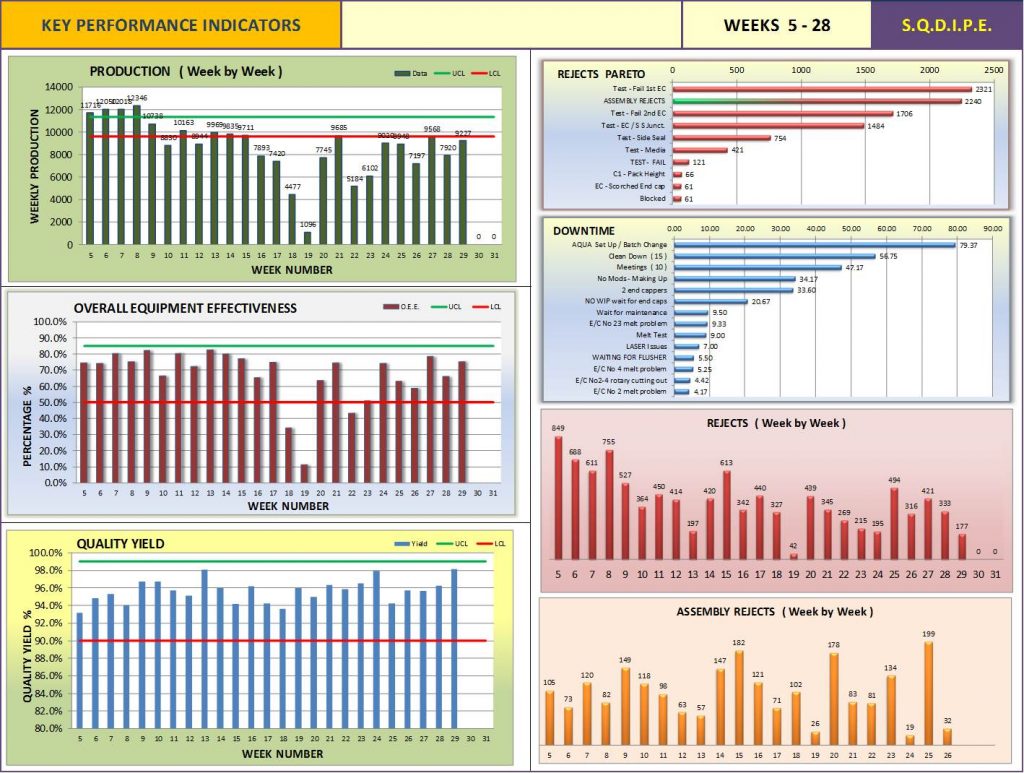

Key_Performance_Indicators

- Production Production Numbers

- Quality Yield Numbers

- Downtime Pareto

- Rejects Pareto

- The Cost of Rejects

.

85% OF BUSINESS PROBLEMS ARE WITH THE SYSTEM

Edwards Deming said:-

Adopt The New Philosophy:

- Design products and services to meet customers’ needs.

- Put your customers’ needs first, rather than to competitive pressure.

- Look at how the process is carried out – Not just numerical targets.

- Provide support and resources so that production levels and quality are achievable.

- Create your “Quality Vision” and implement it – “Fit For Purpose” not cheap and nasty.

- KEEP IT SIMPLE – REDUCE VARIATION – INCREASE PRODUCTION – INCREASE SALES

.

Non-Conformance-Report…NCRs

NCRs:- customer complaints – poor quality product – poor customer service – supplier issues – internal issues. drawing not correct – parts not to spec – mistakes made by human error etc, etc…

- The cost of doing nothing – will cost the business BIG MONEY

- The cost of doing nothing – would cost £££ in customer complains

- The cost of doing nothing – could cost in lost customers & business

.

We Offer You Hands-On-Help to Improve Processes and Reduce Costs

.

REDUCING COSTS: Is About “Reducing Non-Value Waste”

Reducing Waste: STARTS WITH “A FRESH PAIR OF EYES” And Experience

Over the years we’ve generated for clients £50k to £2.0M per project. Ave Return On Investment 13/1

.

- We offer hands-on-help to Identify Opportunities – Measure present state. Analyse, Develop New ideas. Implement Sustainable Change. Reduce Costs

- Process Mapping – Plant & Factory Layout Design – Time and Motion – Work Study – Method Study… Warehouse Organisation – Quality Awareness – Data Collection On Machine Down-time – Cost Reduction

.

With a 10 minute conversation – A Reduction of meetings increased production valued at circa £187,000

With a 5 minute conversation we helped a company improve production & reduce costs by circa €500k

We helped a company reduce Customer Complaints by analysing NCRs – valued at circa £88,000

We helped a company increase production by circa 30% by implementing quality improvement

We helped a company reduce machine breakdowns, circa 31% by implementing TPM

.

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail