TIME & MOTION STUDY: Industrial Engineer & Consultant Services

WE HELP Manufacturing Companies Improve Process & Productivity – Reduce Business Costs – WE ARE Work Study and Time & Motion Study Engineers UK

.

How Can I Help You Improve Your Business ?

.

WATCHING PEOPLE WORK: “With A Fresh Pair Of Eyes”

I have over 30 years experience, knowledge and expertise in Work Study Time & Motion Study, Industrial Engineering – Help Reduce Costs

.

If I May Ask:- What part of your business is giving you most grief and what would you like to improve first – How can I help you?

.

Our Services: Hands-On-Help, Improve Process, Productivity, Reduce Costs Analyse Work Methods. Carry out Time Studies. Apply Targets. Bench-mark operations to maximise production. And help you develop your WCM profile

How Can I Help You, With Your Ideas

.

Time & Motion Study Expertise Is In “Watching People Work”

.

TIME & MOTION STUDY:

OUR SERVICES:

- Analyse Operator Down-time

- Analyse Present Methods Of Work

- Implement Best Work Place Layouts

- Implement Best Practice Work Methods

- Write SIMPLE Operational Work Procedures

.

.

CYCLE TIME MEASUREMENT:

OUR SERVICES:

- Time Operations

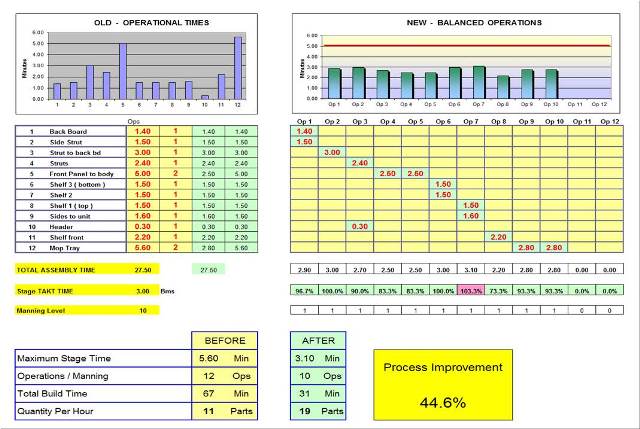

- Balance Flow Lines

- Organise Bench Layouts

- Bench-mark Operation Times

- Set Work Targets – Hourly or Daily

.

- “Best Practice Methods” – Implemented by using LEAN Manufacturing Principles and 30+ years experience

- “A STANDARD TIME” – Implemented to produce the right time for a work operation to maximise production

- The BSI100 Standard Rating Scale – To analyse peoples work rate (some people work slowly, others briskly)

- Setting TARGETS – Applied to Bench-mark operations. Times used for Costing Product, Production Planning

- LEAN Line Balancing – Will balance production through-put. Improve manning, production and reduce costs

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail