PROCESS MAPPING: Service Improvement Engineer & Consultant UK

WE HELP Manufacturing Companies: Process Mapping Techniques Services – Reduce Costs – WE ARE Process Mapping Improvement Engineers UK

.

How Can I Help You Improve Your Business ?

.

PROCESS MAPPING and VALUE STREAM MAPPING:–

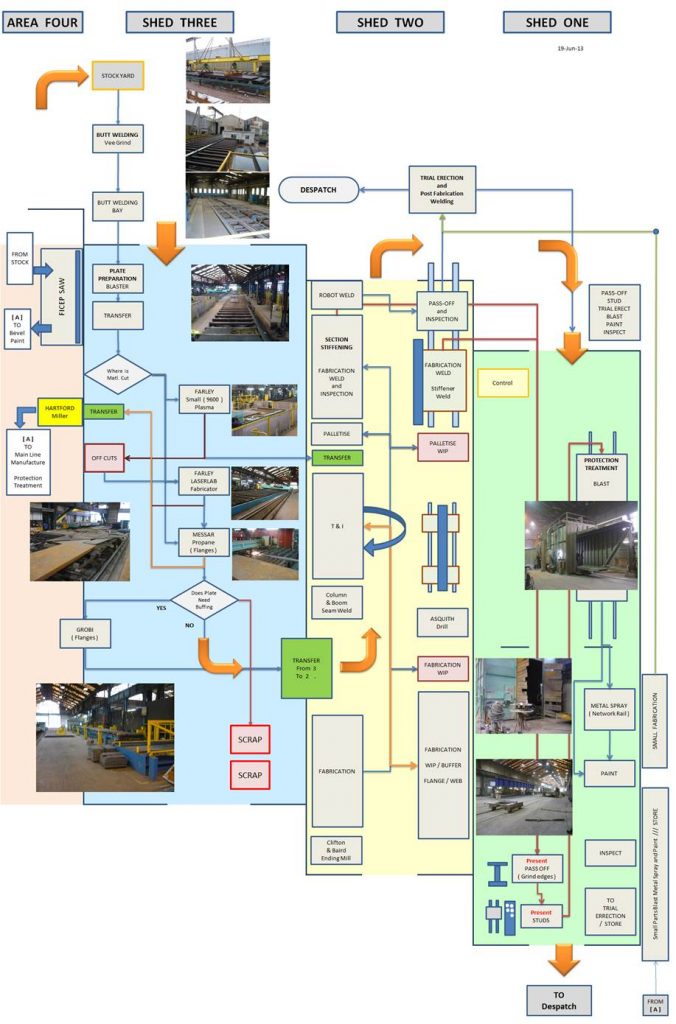

Process Mapping Engineering:- Finding HOW your business processes work. Finding out WHAT people are really doing NOW

Value Stream Mapping Engineering Process:- Is visually mapping or charting the “flow of work”… materials – information – production – people

- 1. To find the entire Value Stream “From Enquiry to Delivery“

- 2. To remove Non-Value Waste. in order to improve

- 3. To improve process, productivity, profit

.

How Can I Help You, With Your Ideas

.

We Offer You Hands-On-Help to Improve Processes and Reduce Costs

.

This factory is 400,000 sq.ft

.

PROCESS MAPPING SERVICES:

- We Identify Opportunities

- Develop Process Improvements

- Develop Solutions – Reduce Costs

- Lets Find Out Who Does What, When

- Lets Find Out What People Are Doing

- Lets Find Out What People Are NOT Doing

- Lets Map the Process and Value Stream

- Lets Map What Improvements Can Be Made

- Lets Document What People Are Doing Now

- Lets Document What People Should Be Doing

- Lets See What Cost Savings Can Be Made

.

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail