FACTORY LAYOUTS: AutoCAD Engineer & Consultant Services UK

WE HELP Manufacturing Companies Improve Factory Organisation – Reduce Business Costs – WE CAN Design Layout Declutter Factory Shop-floor Workplace UK

.

How Can I Help You Improve Your Business ?

.

FACTORY LAYOUT DESIGN:

- Factory Layouts Have To Work

- Factory Layouts Have To Be Clutter Free

- Factory Layouts Have To Be Flexible & Efficient

- Room For Expansion and Future Growth

- Production Needs To Flow ‘Be Pulled’

- Factory Layouts Have To Be ‘Safe’

.

.

OUR SERVICES:

- Present Floor Layout Drawing

- Factory Floor De-clutter Service

- Factory Floor Layout Organisation

- New Factory Floor Layout Implementation

- Process Mapping or Value Stream Mapping

- Single-Piece-Flow or Production Line Balancing

.

.

COMPANY BENEFITS:

- Improved Floor Layout

- Improved Floor Organisation

- Improved Cash-in-Bank & Profit

- Improved Business Growth Potential

- Spare Cash To Purchase New Equipment

- Reduced Stress Levels

.

.

How Can I Help You, With Your Ideas

.

Factory Floor Layout Improvement and Organisation:

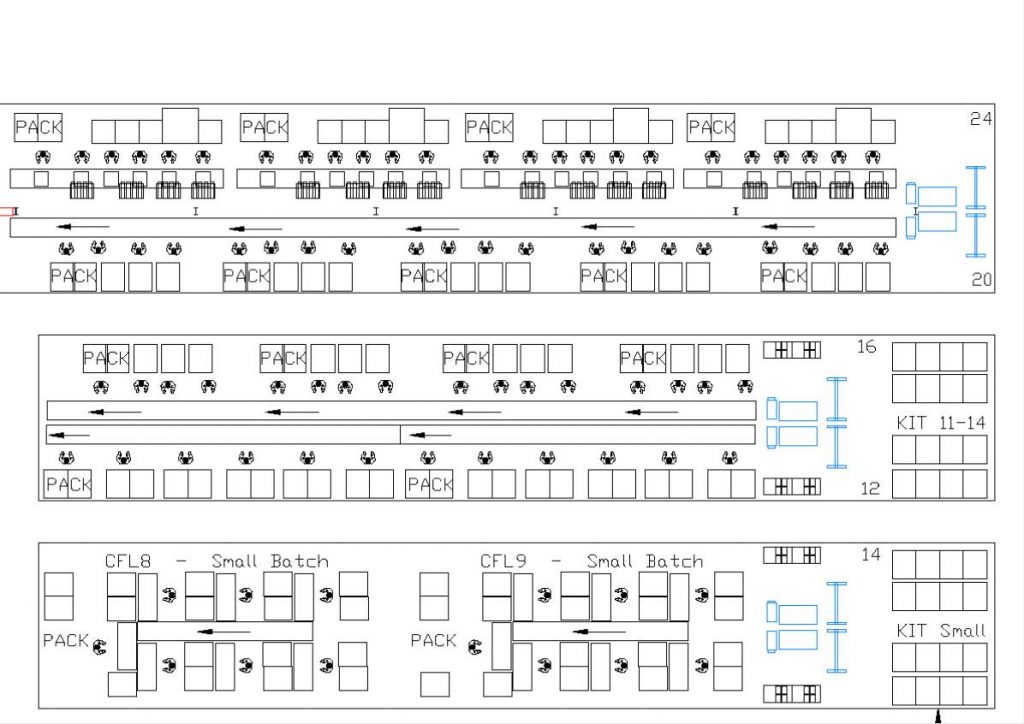

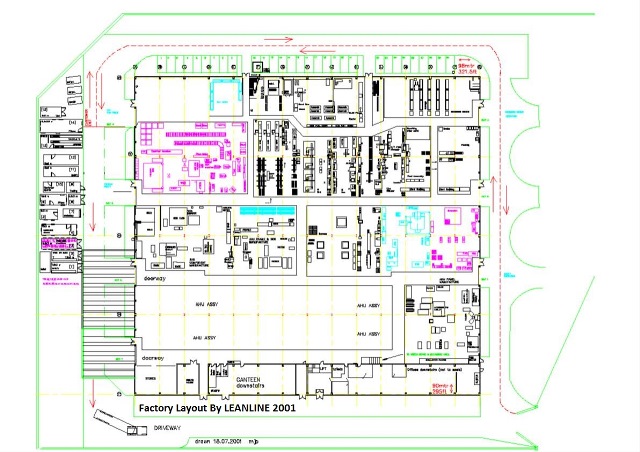

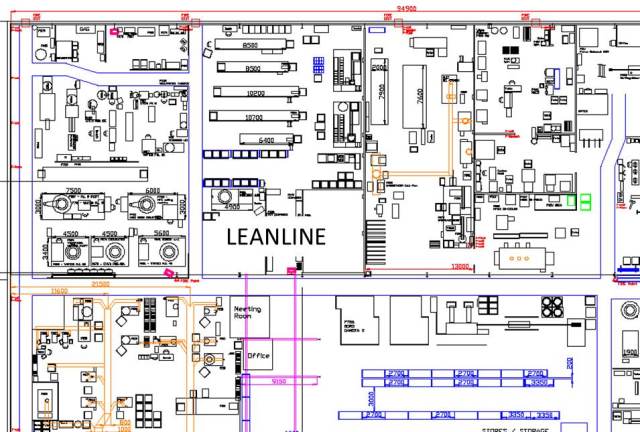

We can help you engineer a LEAN factory shop-floor & plant layout. Design balanced & single-piece flow-lines, process layout improvement and organisation.

.

AutoCAD Factory Floor Layout Design Engineering

We can help you draw and dimension the Present State Layout. Design and organise a Future State Plant Layout… Re-engineer an assembly line, Kitting Area, WIP, Kanbans. The new layout would give production greater flexibility

.

We Can Help You With:

- Greenfield Plant Layout Planning

- Single-Piece Flow-Line Design

- Balanced Flow-Line Design

- Plant Layout Improvement

- Project Management

We Can Help You Project Manage Change

- We give hands-on-help:- We Identify opportunities – Measure Present State – Analyse and Develop ideas – Implement Future State Solutions…

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail