FACTORY LAYOUTS – Lean Line Balancing – AutoCAD Engineers

We Help People In Manufacturing Improve Process and Productivity – Reduce Business Costs – We Can Help You Improve Your Floor Layout and Workplace Organisation

.

What.are.your.daily.issues ?

- Bottlenecks

- Waiting Time

- Looking For “Stuff”

- Workplace Not Organised

- Lack of Inventory Organisation

We.can.help you:

- Draw Plant Floor Layout

- Improve Your Factory Layout

- Improve Inventory Organisation

- Improve Workplace Organisation

- Improve End-to-End Production Flow

Financial Benefits:

- Improved Productivity

- Improved Cash and Profits

- Improved Customer Satisfaction

- Improved Business Growth Potential

Services We Offer:

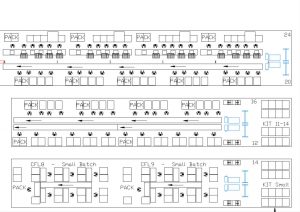

Factory Floor Layout Design:

We can help you create a LEAN factory layout, design balanced flow-lines, single-piece-flow lines, re-engineer a work cell or organise a bench layout. Layout Planning will reduce bottle-necks, improve ‘End-to-End’ production time… Change will improve efficiency, productivity, profit. Also reduce your environmental footprint…

.

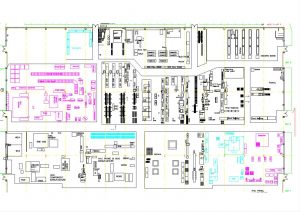

Manufacturing Plant Layout Design:

We can help you create a LEAN manufacturing plant layout design. Analyse machine OEE. Implement TPM & SMED. Reduce machine breakdowns, stoppages, rejects and scrap levels. Improve machine reliability and machine up-time…

.

LEAN Line Manufacturing:

LEAN Line Manufacturing Principles will reduce down-time and improve the flow of production through the shop-floor. Thus improving operator or machine efficiency and reduce costs.

.

LEAN Line Balancing

LEAN Line Balancing Principles are used to level operations, Time and Motion Study will highlight the opportunity. Huge productivity and time gains, TAKT TIME or operator targets will improve production planning.

.

LEAN Line Design

LEAN Line Design can take the form of “Single-Piece-Flow” – Management have control of production through-put. Production is PULLED through – Assembly Time can be greatly reduced – Space better utilised – training simplified.

.

AutoCAD Floor Layout Engineering:

AutoCAD Engineering is the key to drawing the Present State or Future State Plant Layout – Maybe re-engineering a new assembly line incorporating kitting area, Kanbans, Supermarkets etc. The new layout could be implemented to allow variation in customer demand giving greater flexibility.

.

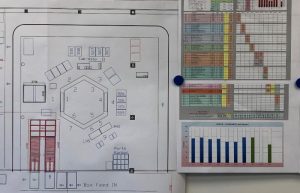

Factory Layout Planner and Project Manager

- We look for Non-Value Waste. “Time – Inventory – Movement – Waiting – Over-processing – Over-production – Downtime – Machine OEE – Reject and Scrap Costs”…

- We give hands-on-help:- We Identify opportunities – Measure Present State – Analyse and Develop ideas – Implement Future State Change…

- We Re-designed 3 warehouses, implemented inventory stock level organisation – cash gain circa £1.9M

- We Implemented Process improvement giving 27% extra – projected sales improvement worth £2.0M

If You Have Any Questions, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project…

For over 30 years we’ve designed and implemented “Continuous Improvement” Projects.

Atherton Management Services Ltd: We help people in business improve their business.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

For More Information – Please call us… UK – 07300 788 486 or Contact Us By E-Mail