QUALITY IMPROVEMENT: Engineer & Consultant Services UK

WE HELP Manufacturing Companies with Quality Improvement Engineering and Reduce Costs – WE ARE Process & Quality Improvement Engineers UK

.

How Can I Help You Improve Your Business ?

.

CUSTOMERS EXPECT QUALITY – NOT Once, But Every-Time – “Nearly Right” Is Not Good Enough

THE COST OF POOR QUALITY – Customer Complaints, NCR’s “Human Error” You will lose customers

.

.

CUSTOMERS WANT:

- 1.RIGHT PRICE

- 2.QUALITY at 100%

- 3.CONSISTENT QUALITY

- 4.BEST QUALITY SERVICE at 100%

- 5.DELIVERY When the Customer Wants It

.

.

PRODUCTION ISSUES:

What Is Your Biggest Headache At Work?

Managers, Supervisors & Directors spend a lot of time in meetings every day. Discussing yesterdays problems and tomorrows production plan

BUT ALSO: Quality Issues – Customer Complaints – Rejects – Human Error… Trying to identify “What When Wrong”

.

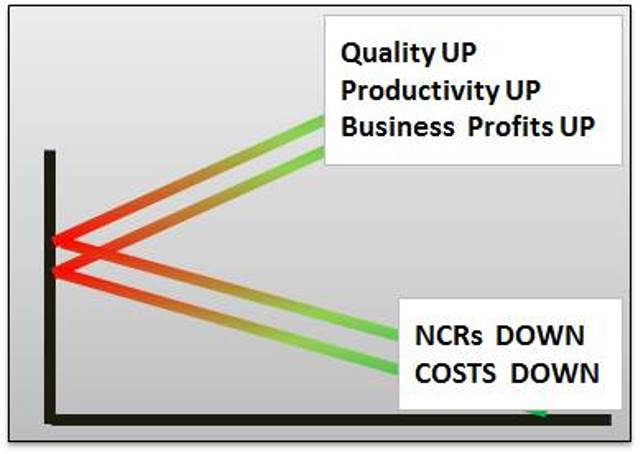

BUT:- What is the cost of NCRs, Rejects, Scrap, Lost Production etc?

We Can Implement Simple Measures To Improve Quality and Profit

.

How Can I Help You, With Your Ideas

.

People Talk About Problems – We Find The “Root Cause” and Fix It

.

OUR SERVICES;

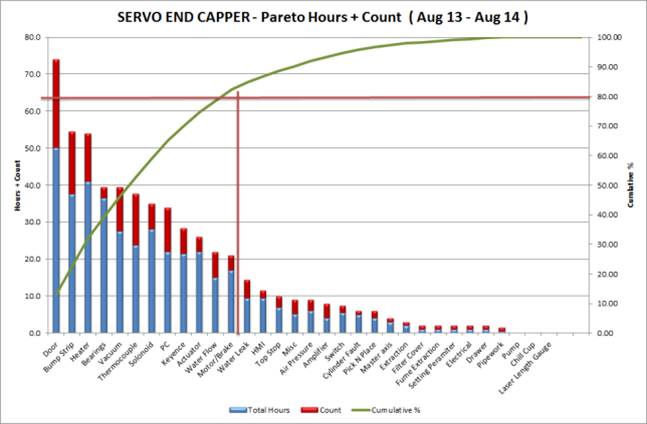

- Analyse Quality Issues

- Analyse Customer Complaints

- Analyse By Using Pareto Charting

- Put Things Right – With A 100 yr Fix

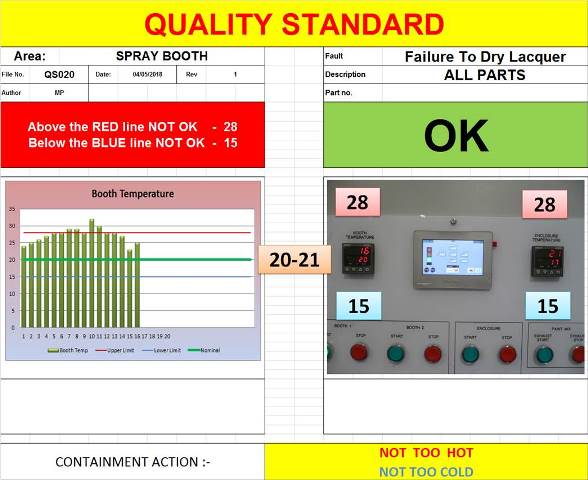

- Write SIMPLE Standard Op Procedures

- Write SIMPLE Quality Awareness Standards

.

.

SIMPLE Things To Improve Quality & Profit:

- Design OUT Possible Rejects

- Design OUT Complicated Designs

- Design OUT the “Human Error” Factor

- Design IN Standardisation & Reduce Variation

- Design IN Simple Product Design and Process

- When Quality Goes UP – COSTS GO DOWN

- When Quality Goes UP – Company Growth Goes UP

.

We Offer You Hands-On-Help to Improve Processes and Reduce Costs

.

.

Quality Counts – “If You Don’t Get It Right, Someone Else Will”

“It Can Take a Long Time to Get a Customer – One Mistake Can Lose Them“

.

Tell Me Your Ideas – I Can Help You Achieve Them

Please Contact Us:- UK – 07300 788 486 – or by E-Mail