How To Improve Processes In The Manufacturing Workplace

How To Improve Processes & Reduce Costs in the Manufacturing Industry Workplace – Life Science Case Study Implemented

.

Case Study Implemented – Life Science: Continuous Improvement

- OBJECTIVES:- To reduce machine breakdowns and stoppages – To Improve quality and production…

- RESULTS:- Reduced stoppages and breakdowns – Improved product quality & production numbers…

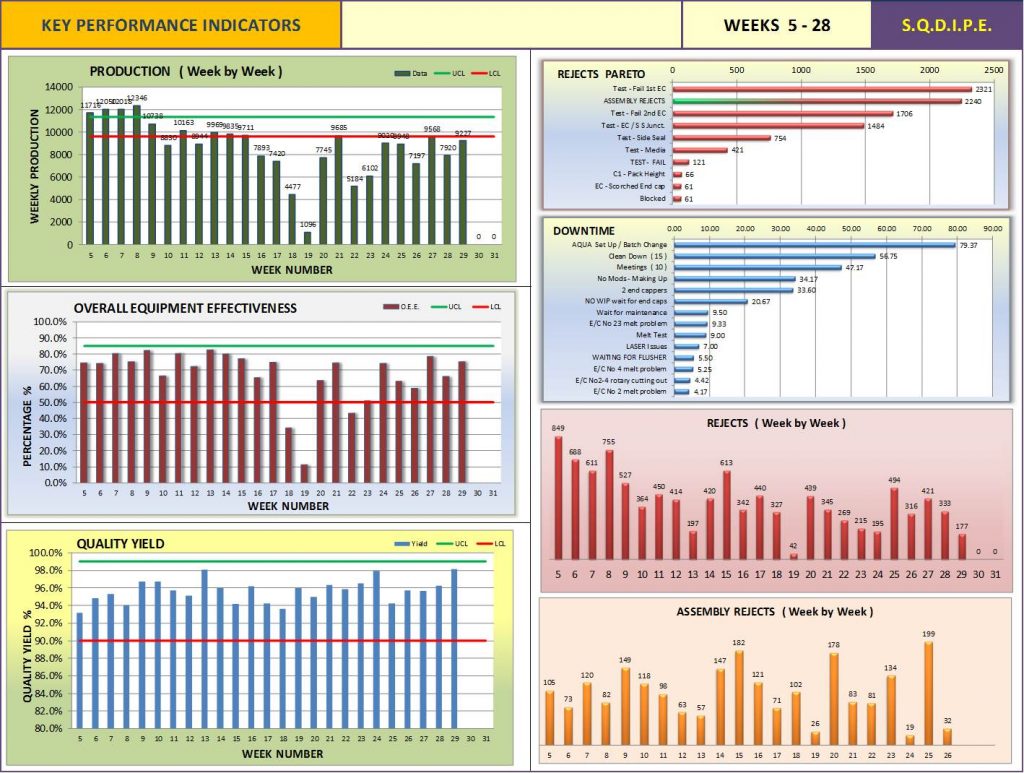

- BENEFITS:- Visual Management “KPIs” Introduced to improve production and create higher profits

.

PROJECT WORK DONE:

- Introduce Key Performance Indicators and data collection…

- Introduce and implement CI – OEE – TPM – SPC…

- Write Standard Operation Work Procedures…

- Write TPM Planned Maintenance Procedures…

- Invest a small amount of capital on plant…

- Catalyst For Continuous Improvement Team Events…

.

FINANCIAL BENEFITS:

- £15,000 – From Quality Improvement

- £187,000 – From Process Improvement

- £187,000 – From Meeting Re-alignments

- £14,000 – From Design For Manufacture

- £90,000 – From Statistical Process Control

- £359,000 – From Total Planned Maintenance Introduction

- £75,000 Saved – From investing £20,000 in new plant & machinery

FINANCIAL BENEFITS:

This Project Potential Savings Per Annum circa £900k

.

We Help People Identify Opportunities for Improving Business and Implement Change

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Return On Investment; Client savings compared against contractor costs. Recent average circa R.O.I. 13 / 1

Please Contact Us:- UK – 07300 788 486 – or by E-Mail…