PROBLEM SOLVERS – Manufacturing LEAN Engineering Services

We Help Manufacturing Companies with Problem Solving in the Work Place and Reduce Costs – We Are Process Improvement Engineering Experts 30+ yrs

.

Business Support For The UK Manufacturing Industry:-

.

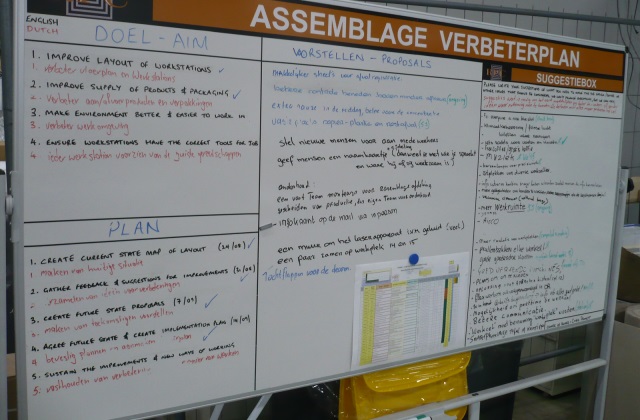

OPPORTUNITY – PLAN – DO

WHAT IS A PROBLEM SOLVER:

- We Are Problem Solvers / Project Managers: Specialists in improving manufacturing processes and efficiency. With a continuous improvement strategy to reduce costs and improve your business growth potential.

- We design and organise factories to improve processes.

- We find, drive and implement process improvements.

- We implement improvements to increase profits.

- Tell Me Your Ideas – I Can Help You Achieve Them

.

- We Can Help:- Factory Layouts – Process Methods – Product Build Time – Product Quality – Tooling Issues – Machine Down Time – Scrap and Rejects – Materials Organisation – Manning Levels – Written Procedures – Energy Management – Analysis and Synthetics of Production Data..

.

We Can Help You Improve Processes & Reduce Costs

.

LETS ASK SOME QUESTIONS:

People:- When you walk around the shop-floor:- How many people are idle, discussing a problem, maybe just talking?

Machines:– How often are machines stopped or broken down needlessly – How much production is lost or scrapped?

Quality:– Product has to be “Right First Time” otherwise production is lost – How much does re-making parts cost?

Time:– How much time is lost in remaking a job? – How much more production could you be doing?

Inventory:– When parts are needed can it be found – How much has been on the shelf “for ever”

Deliveries:- What is the financial cost to the business in late deliveries?

What keeps you awake at night (work only)?

.

If You Improve Processes – You Reduce Costs – You Improve Profits and Cash Flow

.

Tell me what ideas you have and i can help you achieve them

.

We helped a company improve production and reduce costs by circa €500k with a 5 minute conversation

We helped a company increase production by circa 30% by applying Activity Sampling techniques

We helped a company reduce machine breakdowns, circa 31% by implementing TPM

.

Client savings compared against / contract costs. circa R.O.I. 13 / 1

We Help People In Manufacturing Improve Processes and Reduce Costs

.

Atherton Management Services Ltd

.

We Are Problem Solvers, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail