TIME & MOTION STUDY – Industrial Engineer & Consultant Services

We Help Manufacturing Companies Improve Process and Productivity – Reduce Business Costs – We Help Improve Work Methods, Set Time Study Standards.

.

WE WATCH PEOPLE WORK – Improve Production & Efficiency

.

Problems You May Have:

- Job Taking Too Long

- Poor Method of Assembly

- Picking / Kitting Taking Too Long

- Not Meeting Customer Deliveries

- Want To Reduce Your Business Costs

- We Can Help You Implement Your Ideas

.

Services We Offer:

.

Time and Motion Study:

Time & Motion Study Expertise Is In “Watching People Work”

We have over 30 years experience, knowledge and expertise in Work Study and Time & Motion Study Principles. And help business reduce costs

We look for “Non-Value Waste”. Waste in Time – Inventory – Movement – Waiting – Over-processing – Scrap – Rejects – OEE – Machine down-time.

We give hands-on-help:- introduce “Best Practice Methods” Using LEAN Manufacturing Principles and methodologies to improve process, productivity and Reduce Costs

.

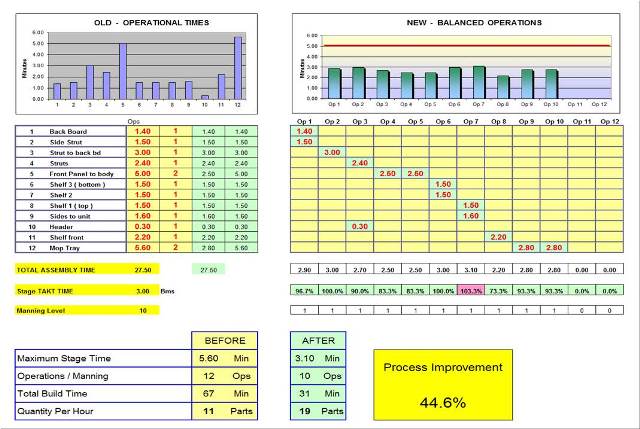

Cycle Time Measurement:

We Can Help You With:

- Time Operations

- Balance Flow Lines

- Organise Bench Layouts

- Best Practice Process Methods

- Bench-mark Operation Times & Targets

.

We can establish a “STANDARD TIME” for an operator to carry out a job… Using a Stop Watch, NOT Mobile Phone…

- We analyse peoples work rate (some people work slowly, others briskly) The BSI100 Standard Rating Scale is applied to produce the right time for a work operation…

- TAKT TIME and TARGETS can then be applied to Bench-mark operations… Costing, Production Planning and planning for on-time deliveries…

- LEAN Line Balancing will balance production through-put – To improve manning, production and reduce costs

We Help People In Manufacturing Improve Processes & Reduce Costs

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail