TOTAL PRODUCTIVE MAINTENANCE – TPM Engineer & Consultant

We Help Manufacturing Companies Implement a PRO-ACTIVE Productive Maintenance Strategy. Advantages & Benefits are Improved Machine Up-time & Reduced Costs

.

“How Much Are: Machine Stoppages & Lost Production Costing Your Business”

.

Total.Productive Maintenance Benefits:

- Reduced raw material costs

- Reduced lost production costs

- Reduced machine repair costs

- Reduced non-value scrap costs

- Reduced Health & Safety Issues

- Reduced in-visible business costs

We Can Implement Simple Measures To Eliminate Down-time

.

Financial Benefits:

- Improved M/c Up-Time

- Improved Product Quality

- Improved Plant Productivity

- Improved Cash In Bank and Profits

- Improved On-time Customer Delivery

.

Services We Offer:

.

Planned Maintenance is a scheduled service visit, carried out by a suitable engineer, to ensure that an item of equipment is operating correctly. To therefore reduce or avoid any unscheduled breakdown and downtime.

.

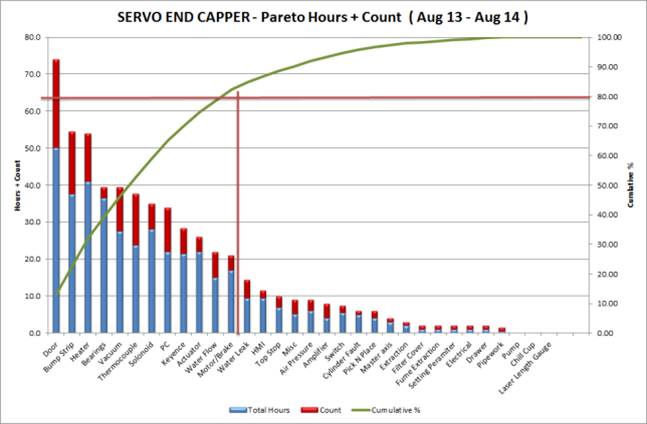

Root Cause Pareto Analysis

Simple TPM Improvement Implementation:

The First Step is to establish what is giving you the biggest downtime headache. The Second Step is to analyse the following:-

- Root Cause – Pareto

- Develop Machine Listing

- Develop Machine History

- Develop Stock Parts Listing

- Develop Servicing Check Sheet

- Develop Housekeeping and H&S Routine

.

TPM Total Planned Maintenance – Simple & Cost Saving Introduction

1.Simple Maintenance: we can help you plan for basic m/c maintenance

2.Planned Maintenance: we can help you plan maintenance to improve production.

3.Quality Management: we can help you write procedures, standardise m/c settings

4.Equipment Management: we can help to improve the shop-floor and plant layout

5.Reliability Engineering: we can help implement change, improve machine up-time

6.Poka-Yoke: ( Mistake-proofing ) to eliminate mistakes in the manufacturing process

7.TRAINING & H&S: along with writing procedures help with training and H&S awareness

8.5S – Sort – Set – Shine – Standardise – Sustain ( a place for everything – everything in it’s place )

.

We are that “independent extra pair of eyes”

Find out what cash could be generated by eliminating down-time

.

TPM IS The KEY to a Better Business and Your Future

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail