PROCESS & PRODUCTIVITY IMPROVEMENT – Visual Management

We Help People In Manufacturing Improve Process and Productivity – Reduce Business Costs – We Can Help You Create Visual Management Boards to Improve Productivity & Efficiency

LEAN .

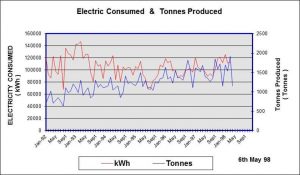

HOW DO I IMPROVE PRODUCTIVITY:- To improve productivity in manufacturing:- 1..Ask What Do I WANT To Know 2..Apply Visual Management 3..Collect Data & Analyse:- Production Numbers – People – Work Hours – Operations.

.

What.are.your.biggest.costs ?

- Labour Costs

- Production Costs

- Rejects and Scrap

- Machine Stoppages

- Customer Complaints

- Costs that are “NOT Visible”

We.can.help.you.with:

- Data Collection

- Data Number Crunching

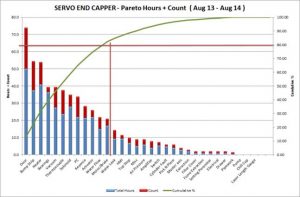

- Analyse Process Down-time

- Analyse Reject & Scrap Levels

- Analyse Operator Non-Value Waste

Financial.Benefits:

- Improved Up-Time

- Improved Productivity

- Improved Cash and Profits

- Improved Customer Satisfaction

- Improved Business Growth Potential

Services We Offer:

Visual Management LEAN Controls

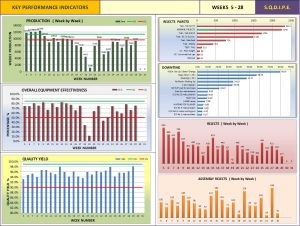

Visual Management is about finding out what is happening with the business. Production Numbers – Quality Yield – Tooling Change-Overs – OEE – Machine Breakdowns and much more…

If you don’t have the information you don’t have control of the business… This will result in the business losing money. We can help you: 1. Identify Opportunities – 2. Analyse The Data – 3. Implement Process Controls…

We can help you improve process, productivity, profits.

- We Instigated and implemented LEAN process improvements – Projected gain £400k

- We Instigated and implemented a reduction in machine breakdowns and rejects – Projected gain £410k

If You Have Any Questions, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project…

For over 30 years we’ve designed and implemented “Continuous Improvement” Projects.

Atherton Management Services Ltd: We help people in business improve their business.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

For More Information – Please call us… UK – 07300 788 486 or Contact Us By E-Mail