QUALITY IMPROVEMENT PROJECTS – Engineering In Manufacturing

We Help People In Manufacturing Improve Process and Productivity – Reduce Business Costs – We Can Help You With Quality Improvement, Quality Awareness and Std Work Procedures

.

STAND IN YOUR CUSTOMERS SHOES:- There is nothing worse than bad service…

It Takes A Long Time To Get A Customer:- Only 1 mistake to lose them

Nearly Right Is NOT Good Enough:- In order to keep customers

.

We Can Help You Turn An Issue Into An Opportunity:

- Poor Quality Starts With Design

- Poor Product Design Produces Rejects

- Poor Processes Produce Lost Production

- Poor Quality Wastes Resources and Electricity

- Poor Quality Management Reduces Profits and Cash

.

We Can Help You:

- Design OUT Possible Rejects

- Design OUT a Complicated Process

- Design IN Standardisation of Product

- Design IN Simple Quality Awareness Procedures

- Design IN Simple Processes to Reduce the Electric Bill

.

Financial Benefits:

- Reduced Rejects and Scrap

- Reduced Having To Remake Product

- Reduced Wasting Time and Energy Costs

- Reduced Land-fill – Increased Cash-Flow and Profits

- Reduced Effects on Climate Change “Towards Net Zero”

Edwards Deming said:-

Adopt the new philosophy:

- Design products and services to meet customers’ needs.

- Put your customers’ needs first, rather than to competitive pressure.

- Look at how the process is carried out – Not just numerical targets.

- Provide support and resources so that production levels and quality are achievable.

- Create your quality vision, and implement it – “Fit For Purpose” not cheap and nasty.

- KEEP IT SIMPLE – REDUCE VARIATION – INCREASE PRODUCTION – INCREASE SALES

.

Services We Offer:

Quality Improvement Project Engineering:

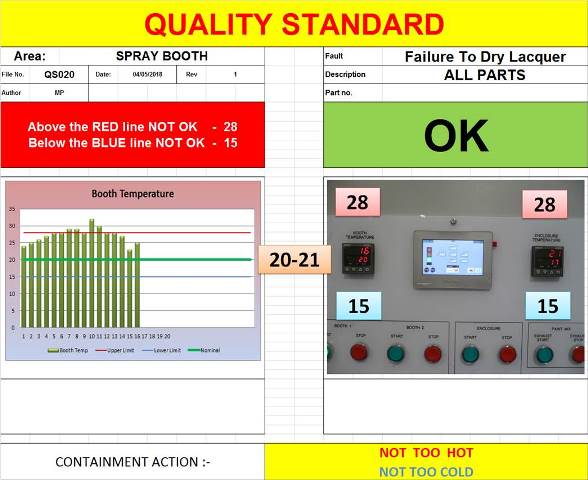

Quality Control Is: We can help you to identify the Root Cause of any quality issues, so product is always “Right First Time” from product design to delivery… The key to quality improvement is; Quality Awareness, Quality Standards and Operator Training.

.

Quality Improvement Engineering:

It is generally understood in management circles that if an instruction, procedure or drawing is written, then everyone will understand them – “This is not always true” – Many procedures can be mis-read or not understood

Temporary contract operators are expected to “do the job” and get the product quality right, without first being trained – Procedures need to be SIMPLE to be understood…

TPM in Quality: If you look after your tools and equipment – Your will maximise your machine up-time and improve production, productivity, and profits…

.

Standardised Quality Work Procedures: We Can Help You With

- Standard Operation Procedures – to improve operator performance and quality.

- Quality Standards – to improve Quality Awareness and customer satisfaction.

- TPM Procedures – to improve up-time, production, productivity, profit.

We Can Help You Up-Skill Your Work-force.

.

If You Have Any Questions, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project…

For over 30 years we’ve designed and implemented “Continuous Improvement” Projects.

Atherton Management Services Ltd: We help people in business improve their business.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

For More Information – Please call us… UK – 07300 788 486 or Contact Us By E-Mail